No-Touch Robotics has received 40,000 Swiss francs in financing from Venture Kick for its contactless robotic grips for small and fragile objects.

The contactless robotic grippers are suitable for industries where damage to small components can result in high costs, such as in the watchmaking or semiconductor industries, explains Venture Kick. The technology also has the advantage that the same gripper can be used for a variety of object shapes, which can save customers time and money.

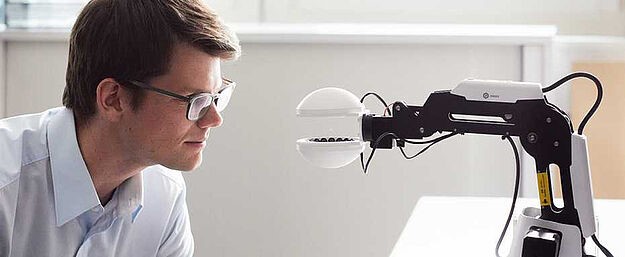

The robotic grippers consist of two semi-spheres, according to a press release from the Swiss Federal Institute of Technology in Zurich (ETH). Using ultrasound waves, the technology generates a pressure field that humans cannot see or hear. Small objects can be trapped within the pressure points, where they appear to float freely in the air between the two semi-spheres.

The user can control the ultrasound waves using a software program, which in turn allows them to move the pressure points around. They can change the position of the pressure points in real time without having the suspended object fall to the ground.

According to Venture Kick, there is currently no other technology in the market capable of providing contactless gripping for objects of various shapes. No-Touch Robotics intends to use the financing to develop its technology further to serve a broader range of applications.

Related news

Meet with an expansion expert

Our services are free of charge and include:

- Introduction to key contacts in industry, academia, and government

- Advice on regulatory framework, taxes, labor, market, and setting up a company

- Custom-made fact-finding visits, including office and co-working space