Rejected goods during production amount to on average 15 percent of costs in industrial manufacturing, the Swiss Federal Institute of Technology in Zurich (ETH) writes in a press release. It mentions often outdated quality management as a reason behind this high factor. Researchers at the ETH have found a solution for this.

Less defective products with the help of the algorithm

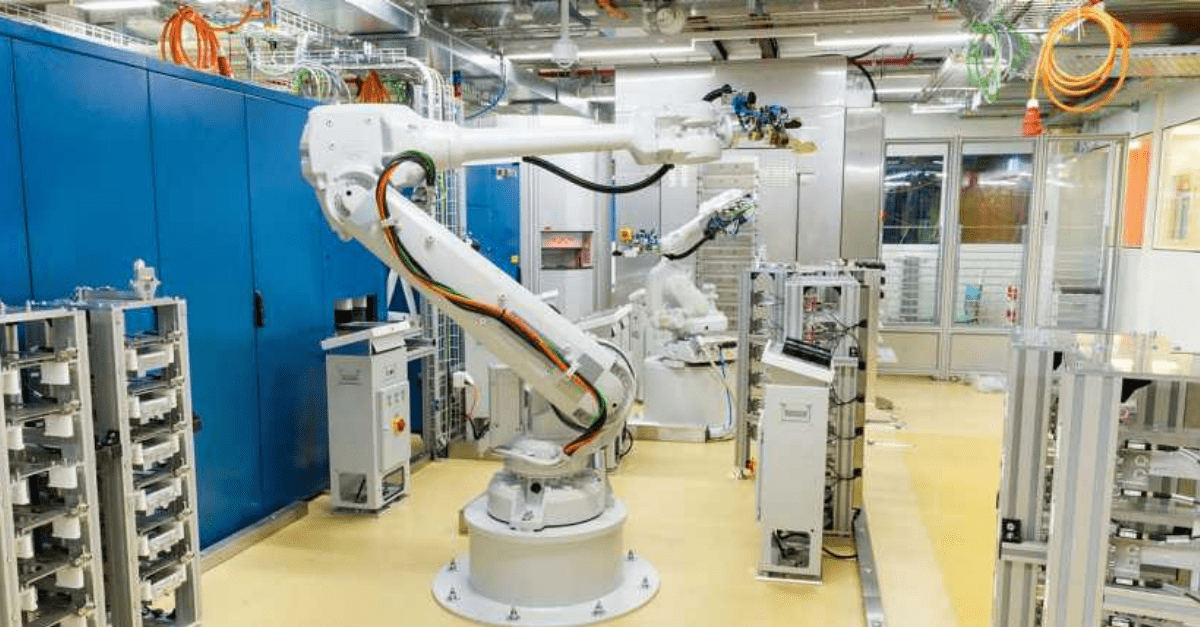

Two ETH researchers, Julian Senoner and Torbjørn Netland, along with Stefan Feuerriegel, who recently joined the Ludwig Maximilian University of Munich, have developed an algorithm that can be used in digitalized production processes. It has already been trialled at industrial partner Hitachi Energy’s semiconductor factory in Lenzburg AG. There, the proportion of defective products was able to be reduced by over 50 percent using the algorithm.

The algorithm based on artificial intelligence imitates the individual steps in complex production processes and is fed with as much historical production data as possible. Lead study author Julian Senoner comments in the press release: “Based on this data, the algorithm learns the conditions needed to ensure good semiconductor quality, and which conditions result in high error rates.”

Netland explains that the approach developed at the ETH aims to “bring quality management into the digital age”. However, this will not replace qualified engineers. The ETH Professor of Production Management explains: “Our algorithm primarily identifies sources of error that have previously gone undetected. But fixing them will still take a great deal of technical expertise and human creativity.”

Possible applications in highly digitized production processes

The researchers see applications for their algorithm in highly digitalized production processes, as currently used in the pharmaceutical and chemical industries or in plastic production. Senoner and ETH Pioneer Fellow Bernhard Kratzwald plan to make the technology as broadly accessible as possible. To achieve this, they have founded the ETH spin-off EthonAI.

Related news

Meet with an expansion expert

Is Greater Zurich on your expansion radar? We support you on every step of your expansion journey - from location evaluation to fact finding visits.

Our services are free of charge and include:

- Introduction to key contacts in industry, academia, and government

- Location evaluation support to find the ideal base for your business

- Advice on regulatory framework, taxes, labor, market, and setting up a company

- Custom-made fact-finding visits, including office and co-working space

- And much more, customized to meet your needs.