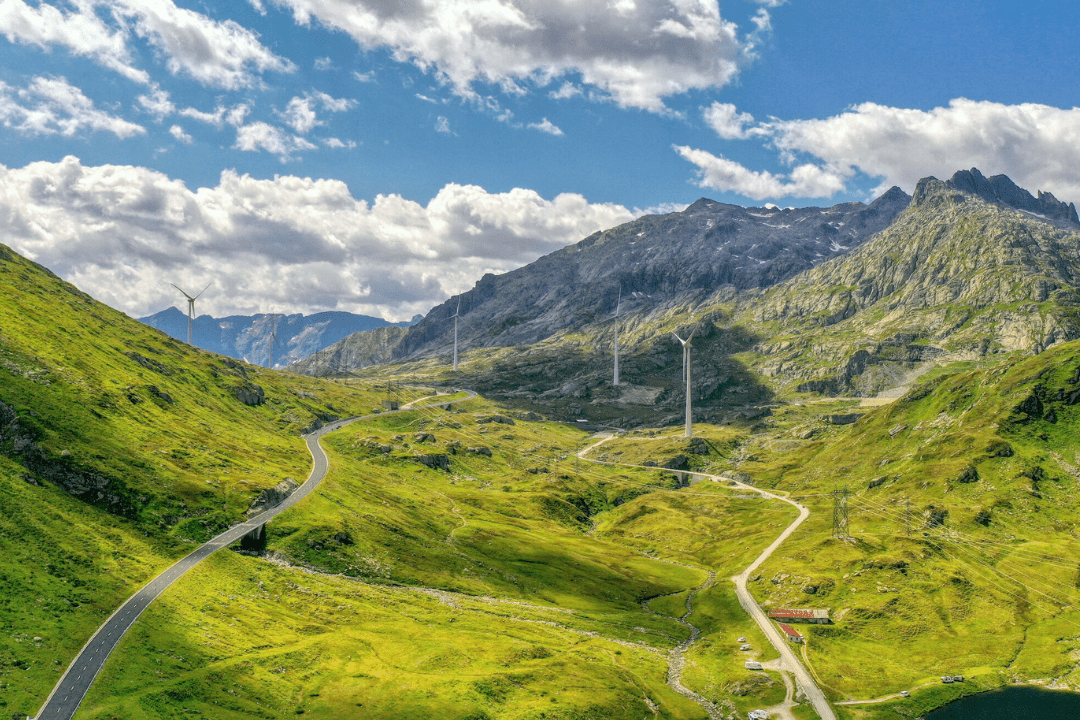

In many areas of sustainability, Switzerland is ahead of the curve: it’s among the world’s best recyclers of municipal solid waste and decarbonised its electricity sector. It also boasts several plans and initiatives to meet its ambitious climate targets. The motivation and foundation for change exists, but there is more work to be done.

Switzerland’s Circularity Metric is 6.9%, slightly below that of the global economy at 7.2%, which leaves a Circularity Gap of just over 93%. This means that most material inputs into the Swiss economy come from the extraction of virgin resources and materials. These are the findings of the first comprehensive study on the state of the circular economy in Switzerland – the Circularity Gap Report Switzerland. The study was produced by the Amsterdam-based Circle Economy and initiated by the Basel-based Circular Economy Switzerland together with the consulting firm Deloitte in Zurich. Impact Hub Switzerland and Kickstart Innovation of Zurich provided support.

Every year, 19 tons of new material are produced for every Swiss citizen. This is what the economy spends on manufacturing products per capita to satisfy the needs and desires of the population, but a sustainable amount would be just 8 tons per capita. The study marks the start of an ambitious initiative with 200 participants from the private and public sectors who want to develop a roadmap for a more circular economy in Switzerland. Companies still resort far too often to freshly mined, natural raw materials. These raw materials are principally sourced abroad, where there are "significant environmental impacts, emissions, and waste".

The manufacturing industry alone accounts for more than 40 percent of the country's material footprint and 36 percent of its CO2 footprint. The construction industry is the second largest contributor to material wear and tear and CO2 emissions, and the food industry comes in third.

"Although these three sectors are very material- and carbon-intensive, Switzerland is well positioned to initiate change," writes the statement. It highlights that great improvements could be achieved in five areas identified by the study, including the promotion of a circular food system and the adoption of a circular lifestyle.

Circular jobs: An important and telling metric to consider is also the share of circularity-focused jobs in Switzerland. This was recently studied in a report by Circle Economy, which concluded that 9.1% of Switzerland’s 5.3 million jobs already contribute to the circular economy. Although this number is relatively high when compared to other countries in Europe (between 5% and 10%), it suggests that Switzerland is still at the beginning of its circular transition.

Circular Economy in the Greater Zurich Area

Circular Economy in the Greater Zurich Area

In the Greater Zurich Area, initiatives, companies and new projects are promoting the circular economy in Switzerland: From packaging, to fish farming, and vertical farming. Discover circular economy initiatives from the Greater Zurich Area in the GZA Annual Report 2022.

Sustainable Business Region Greater Zurich Area

Sustainable Business Region Greater Zurich Area

ESG metrics are increasingly important performance indicators for most sustainable companies. Expanding or relocating a business can have a dramatic impact on these metrics, and Switzerland is the ideal location for meeting sustainability goals.

Related news

Meet with an expansion expert

Our services are free of charge and include:

- Introduction to key contacts in industry, academia, and government

- Advice on regulatory framework, taxes, labor, market, and setting up a company

- Custom-made fact-finding visits, including office and co-working space